Product Description:

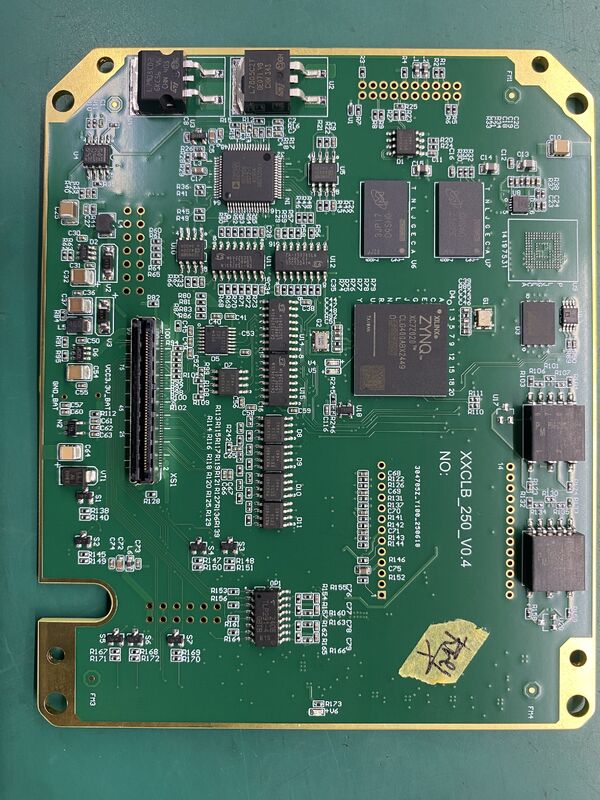

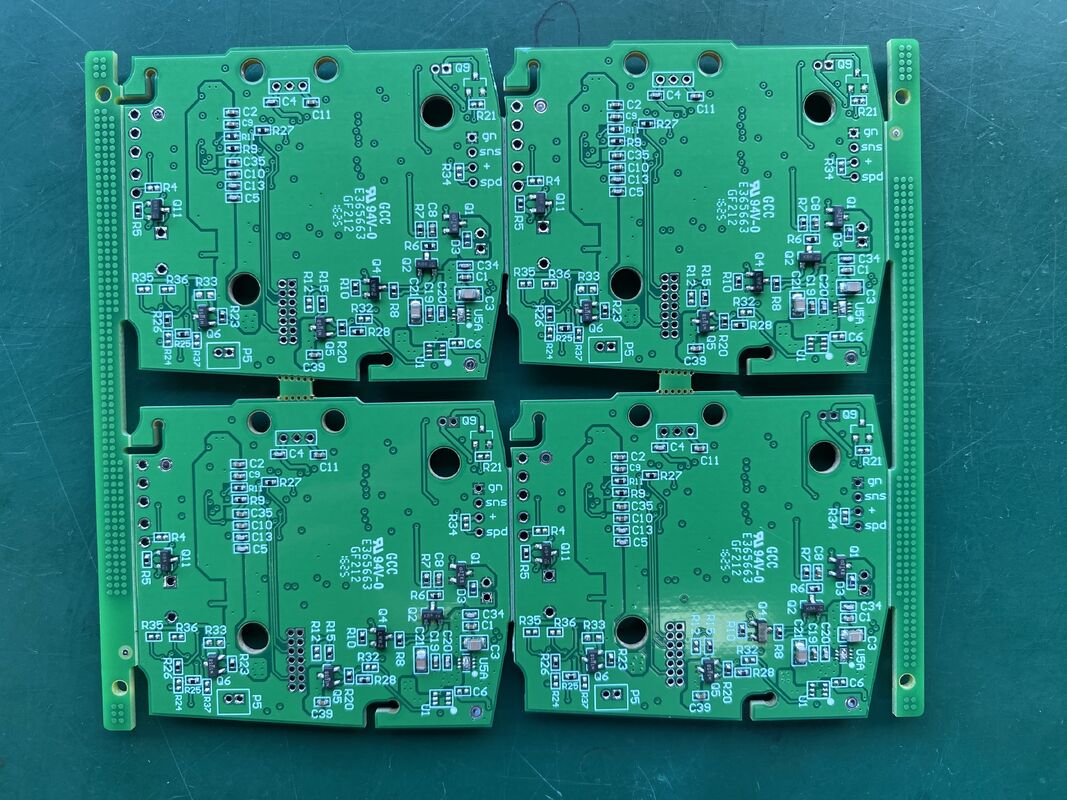

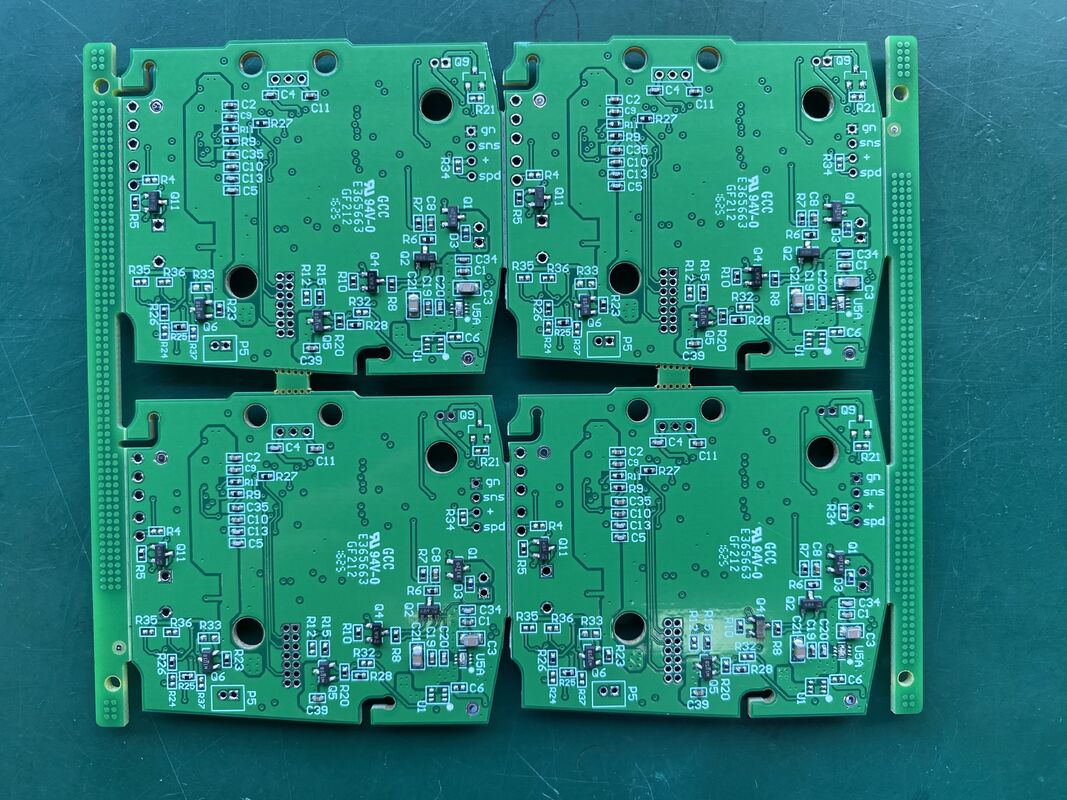

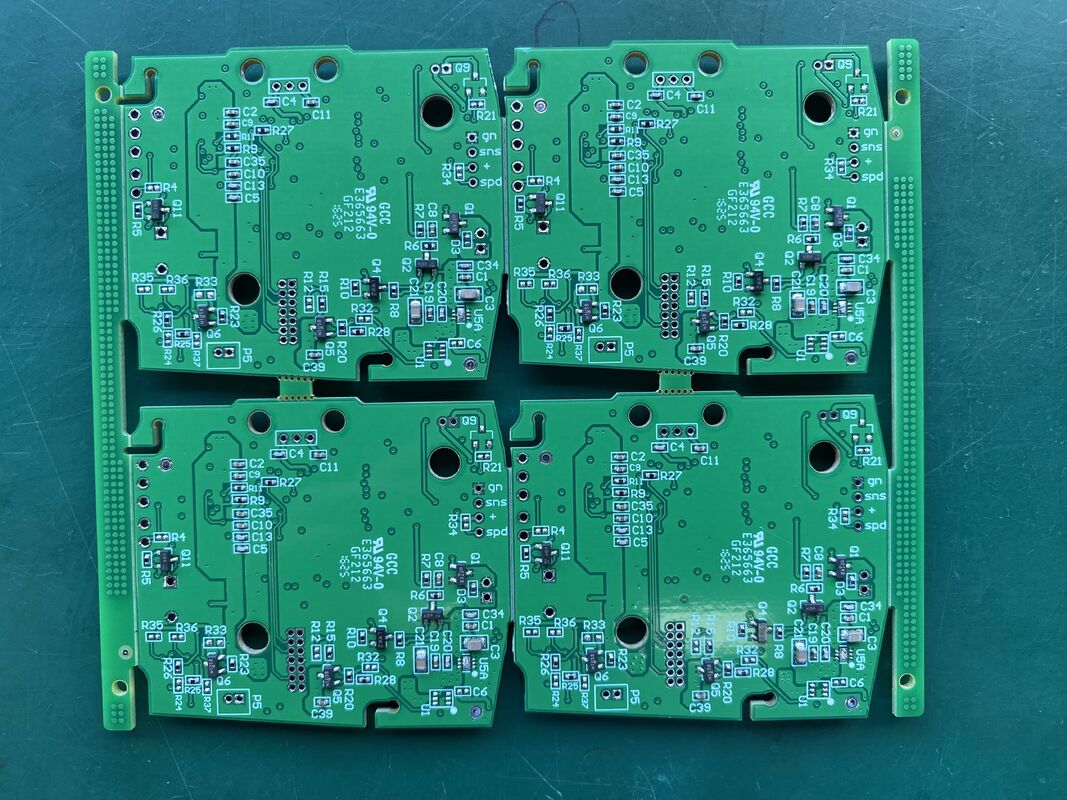

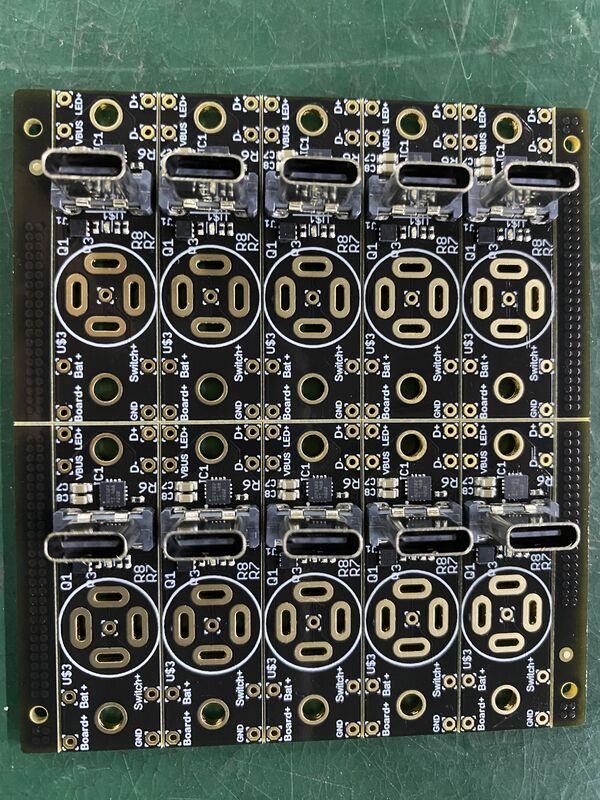

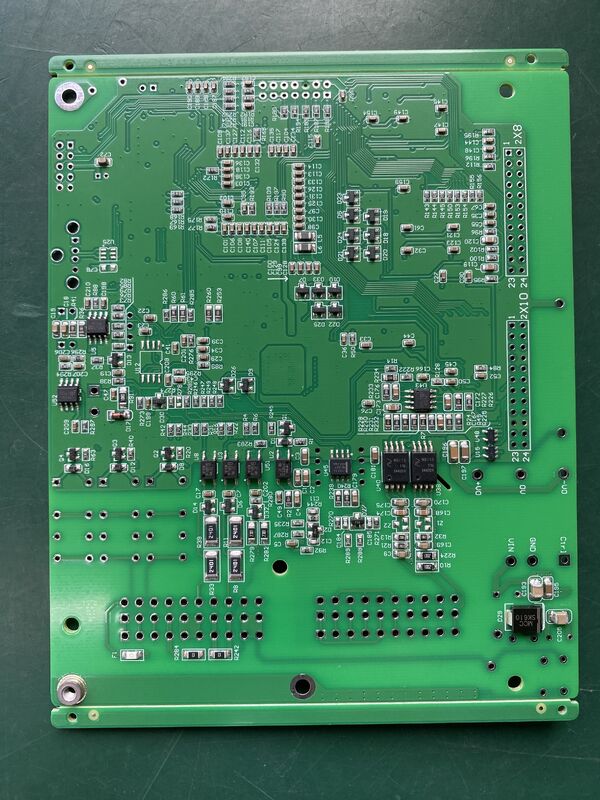

The Communication PCB Assembly is a highly specialized product designed to meet the rigorous demands of modern communication infrastructure. As a manufacturer committed to delivering superior quality and reliability, we utilize advanced HDI (High-Density Interconnect) PCB technology to ensure exceptional performance and compact design. HDI PCBs are known for their capability to support high-speed signal transmission and increased circuit density, making them ideal for communication applications where space and efficiency are paramount.

One of the standout features of this Communication PCB Assembly is its customization capability. Understanding that communication systems vary widely in design and requirements, we offer tailored solutions to meet specific client needs. Whether it is adapting the board size, layer count, or integrating specialized components, our manufacturing process is flexible enough to accommodate unique specifications, ensuring that the final product perfectly fits the intended application.

The PCB board surface finishing options available for this assembly include ENIG (Electroless Nickel Immersion Gold) and Lead-Free HASL (Hot Air Solder Leveling). ENIG finishing provides excellent surface planarity, superior solderability, and enhanced corrosion resistance, which is critical in maintaining long-term reliability in communication devices. On the other hand, Lead-Free HASL finishing aligns with environmental and regulatory standards while offering a cost-effective solution without compromising functionality. Both finishing methods ensure that the PCB assembly meets the highest quality standards required in the communication industry.

Incorporating multiple via types—through hole, blind, and buried vias—this PCB assembly supports complex circuit designs with improved electrical performance and space optimization. Through hole vias provide robust mechanical connections and reliable electrical pathways, while blind and buried vias enable dense interconnections between inner layers without occupying surface space. This multi-via configuration enhances the overall integrity and functionality of the communication PCB, ensuring it can handle high-frequency signals and maintain signal integrity.

Adherence to stringent quality standards is a hallmark of our PCB manufacturing process. The Communication PCB Assembly complies fully with the ROHS (Restriction of Hazardous Substances) directive, guaranteeing that the product is free from harmful materials such as lead, mercury, and cadmium. This compliance not only makes the product environmentally friendly but also ensures compatibility with global market regulations, providing customers with peace of mind regarding safety and sustainability.

Designed specifically for applications within communication infrastructure, this PCB assembly plays a critical role in enabling seamless data transmission and connectivity. Whether deployed in networking equipment, base stations, or communication modules, the product supports reliable operation under demanding conditions. Additionally, incorporating surge protection features within the PCB design helps to safeguard sensitive electronic components from voltage spikes and transient surges, which are common challenges in communication systems. This protection enhances the durability and longevity of the assembly, reducing downtime and maintenance costs.

As a trusted manufacturer, we prioritize the integration of cutting-edge technology with meticulous quality control to deliver Communication PCB Assemblies that meet and exceed industry expectations. Our comprehensive approach, from design customization to advanced surface finishing and multi-via implementation, ensures that each assembly is optimized for peak performance in communication infrastructure applications. The inclusion of surge protection further adds value by enhancing system reliability and protecting critical communication equipment.

In summary, the Communication PCB Assembly is a versatile, high-performance product tailored for the evolving needs of the communication sector. Featuring HDI PCB technology, customizable design options, premium surface finishing with ENIG and Lead-Free HASL, and multi-via configurations, it stands as a robust solution for complex communication circuits. Compliance with ROHS standards and built-in surge protection underscore its quality and reliability, making it an indispensable component in modern communication infrastructure. Partnering with an experienced manufacturer ensures that customers receive a product engineered for excellence and designed to support the critical demands of today’s connected world.

Features:

- Product Name: Communication PCB Assembly

- Application Field: 5G Communication

- Communication PCB: High Tg170 and High Tg180

- PCB Quality System: ROHS Compliant

- Impedance Control: Yes

- Solder Mask Color Options: Blue, Green, etc.

- Designed by a reliable Manufacturer specializing in Communication infrastructure

- Manufacturer ensures high-quality standards for optimal performance in communication devices

Technical Parameters:

| Product Name |

Communication PCB Assembly |

| PCB Layers |

6 Layers |

| Customized |

Yes |

| Impedance Control |

Yes |

| Min Hole Diameter |

0.1mm |

| Solder Mask Color |

Blue, Green, Etc. |

| PCB Board |

HDI PCB |

| Application Field |

5G Communication |

| Surface Finishing |

ENIG, HASL Lead Free |

| Outer Package |

Carton |

| Special Features |

Heavy Current, Surge Protection, Thick Copper |

Applications:

The Communication PCB Assembly is a critical component designed specifically for the advanced demands of the 5G communication industry. As a manufacturer specializing in high-quality PCB solutions, we understand the stringent requirements that come with modern communication systems. This product is engineered with precise impedance control to ensure optimal signal integrity, which is essential for the high-frequency transmissions characteristic of 5G networks. The ability to maintain consistent impedance throughout the board reduces signal loss and interference, thereby enhancing overall communication performance.

With a versatile board thickness range of 0.2-6mm, the Communication PCB Assembly accommodates various design requirements, making it suitable for a wide array of applications within the 5G infrastructure. Whether used in compact mobile devices, base stations, or network routers, the flexibility in thickness allows designers to optimize the physical and electrical properties according to specific needs. The surface finishing options, including ENIG (Electroless Nickel Immersion Gold) and Lead-Free HASL (Hot Air Solder Leveling), provide excellent solderability and durability, ensuring reliable connections even under heavy current conditions often encountered in communication equipment.

This robust PCB assembly is ideal for scenarios where high-performance communication and reliability are paramount. It is widely used in heavy current applications within 5G base stations where stable power delivery and minimal signal distortion are crucial. Manufacturers deploying this product benefit from its superior build quality and consistent performance, which translates into longer service life and reduced maintenance costs. Additionally, the board’s compatibility with various surface finishes allows it to withstand harsh environmental conditions, making it suitable for outdoor communication towers and industrial communication devices.

In summary, the Communication PCB Assembly stands out as a preferred choice for manufacturers focused on delivering cutting-edge 5G communication solutions. Its impedance control, customizable board thickness, and reliable surface finishing options ensure it meets the demanding standards of the communication industry. Whether utilized in heavy current scenarios or compact devices, this product supports the seamless transmission of data, enabling the next generation of high-speed, low-latency communication networks worldwide.

Customization:

Our Communication PCB Assembly product offers comprehensive customization services to meet the specific needs of manufacturers. We specialize in high-quality HDI PCB boards that ensure superior performance and reliability. The surface finishing options available include ENIG and HASL Lead Free, providing excellent solderability and durability for your assemblies.

We adhere strictly to the ROHS PCB quality system, ensuring that all materials and processes comply with environmental and safety standards. Our solder mask colors are available in a variety of options such as blue, green, and others to suit your design preferences.

With a minimum hole diameter capability of 0.1mm, our manufacturing process supports intricate and precise circuit designs, ideal for advanced communication applications. As a trusted manufacturer, we also incorporate surge protection features to enhance the safety and longevity of your communication devices.

Choose our Communication PCB Assembly customization services for reliable manufacturing solutions tailored to your technical requirements and industry standards.

Support and Services:

Our Communication PCB Assembly product is supported by a dedicated technical support team committed to ensuring optimal performance and reliability. We offer comprehensive services including design consultation, assembly troubleshooting, and post-production testing to meet the specific needs of your communication systems.

Our experts assist with component selection, layout optimization, and signal integrity analysis to enhance the functionality of your PCB assemblies. We also provide firmware integration support and compatibility verification to streamline your development process.

In addition, we offer repair and refurbishment services to extend the lifespan of your communication PCBs, along with regular maintenance programs designed to prevent downtime and ensure consistent operation.

Our commitment to quality is backed by thorough documentation and user manuals, as well as training sessions to empower your team with the knowledge to maintain and troubleshoot the assemblies effectively.

Packing and Shipping:

Our Communication PCB Assembly products are carefully packaged to ensure maximum protection during transit. Each assembly is placed in anti-static bags to prevent electrostatic discharge damage, followed by cushioned packaging materials to absorb shocks and vibrations.

The packaged products are then securely packed in sturdy, corrugated cardboard boxes designed to withstand rough handling. For bulk orders, additional internal dividers and padding are used to keep each PCB assembly separated and safe.

We offer various shipping options to meet your delivery requirements, including standard, expedited, and freight services. All shipments are tracked and insured to guarantee timely and secure delivery.

Before shipping, each Communication PCB Assembly undergoes a thorough quality inspection to ensure it meets all technical specifications and customer requirements.

Our logistics team coordinates closely with reliable carriers to provide seamless global shipping, ensuring your products arrive on time and in perfect condition.

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!  Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!